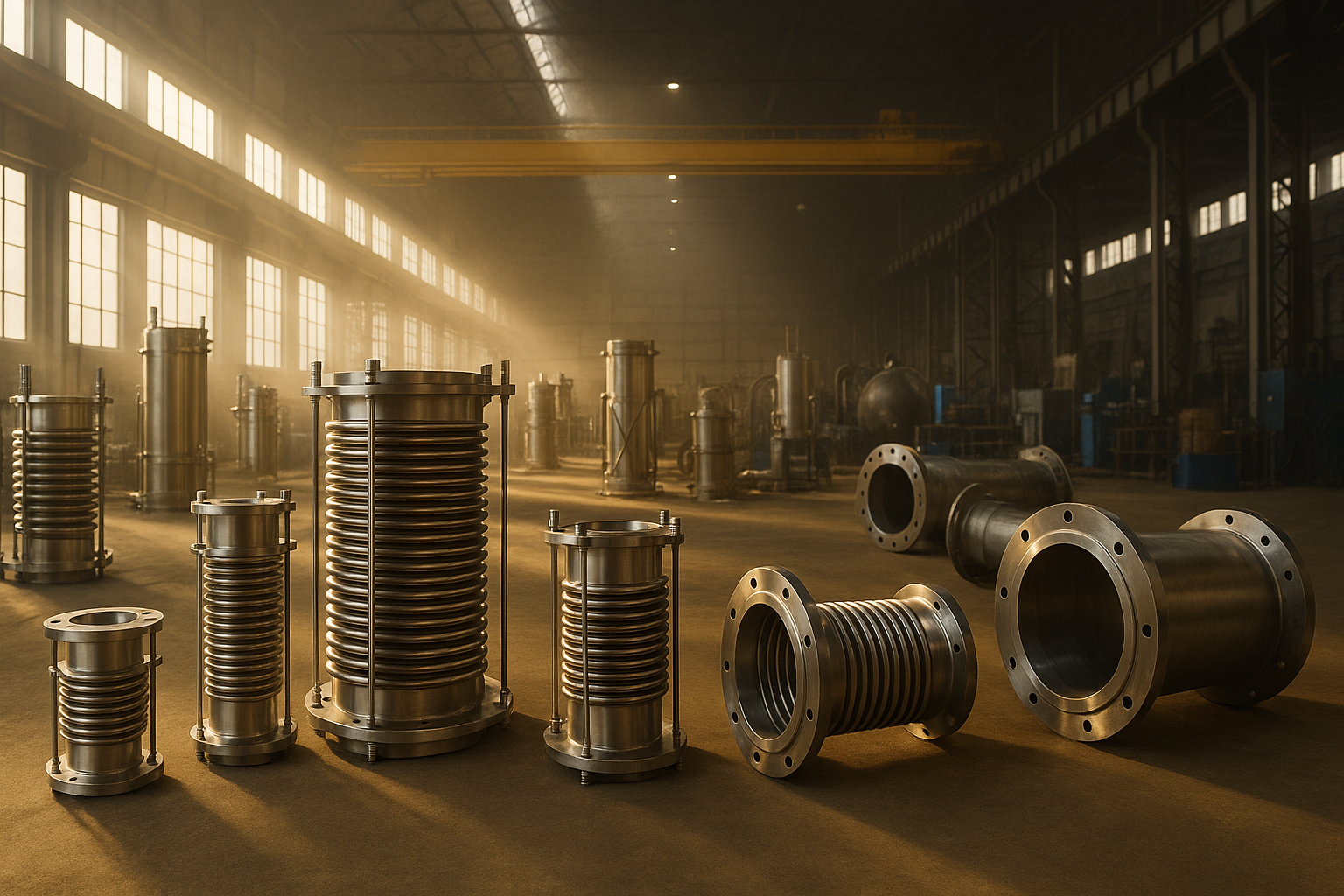

Axial Expansion Bellows

Axial Expansion Joints are designed to absorb thermal expansion and contraction along the pipeline axis, protecting equipment from stress and damage. Manufactured by Athulya Bellows in compliance with EJMA standards, they deliver proven reliability, durability, and safe performance across demanding industries.

Key Features

• Absorbs axial (longitudinal) movements in pipelines.

• Available in single and multi-ply bellows design.

• Manufactured in stainless steel 304, 316, 321, 310 & special alloys.

• Supplied with flanged or welded end connections.

• Options include tie rods, internal liners, and protective covers.

Applications

• Power Plants – steam and condensate pipelines.

• Refineries & Petrochemicals – high-temperature process lines.

• Steel & Cement Plants – hot air ducts and process systems.

• Chemical Industries – corrosive and critical media handling.

• Infrastructure & HVAC – pipelines requiring vibration control.

Technical Data (Typical Ranges)

| Parameter | Range | Notes |

|---|---|---|

| Nominal Size | DN 25 – DN 6000 | Custom diameters available |

| Pressure Rating | Vacuum to high pressure | Project-specific design |

| Temperature | −60°C to +1200°C | Material dependent |

| Materials | SS 304/316/321/310; special alloys | Ends in CS/SS as required |

| End Connections | Flanged / Welded | Drilling standards per spec |

Design Options

• With or without internal flow liners.

• External protective covers & insulation jackets.

• Tie rods / limit rods for transport, preset, or safety.

• Multi-ply bellows for higher flexibility and fatigue life.

• Customized solutions based on client requirements.

Quality & Testing

• Manufactured as per EJMA/ASME practices.

• 100% hydro / pneumatic pressure tested.

• Optional NDT: helium leak, dye penetrant, cycle testing.

• Material traceability with certificates.

Prefer a quick review? Email your specs to sales@athulyabellows.com.