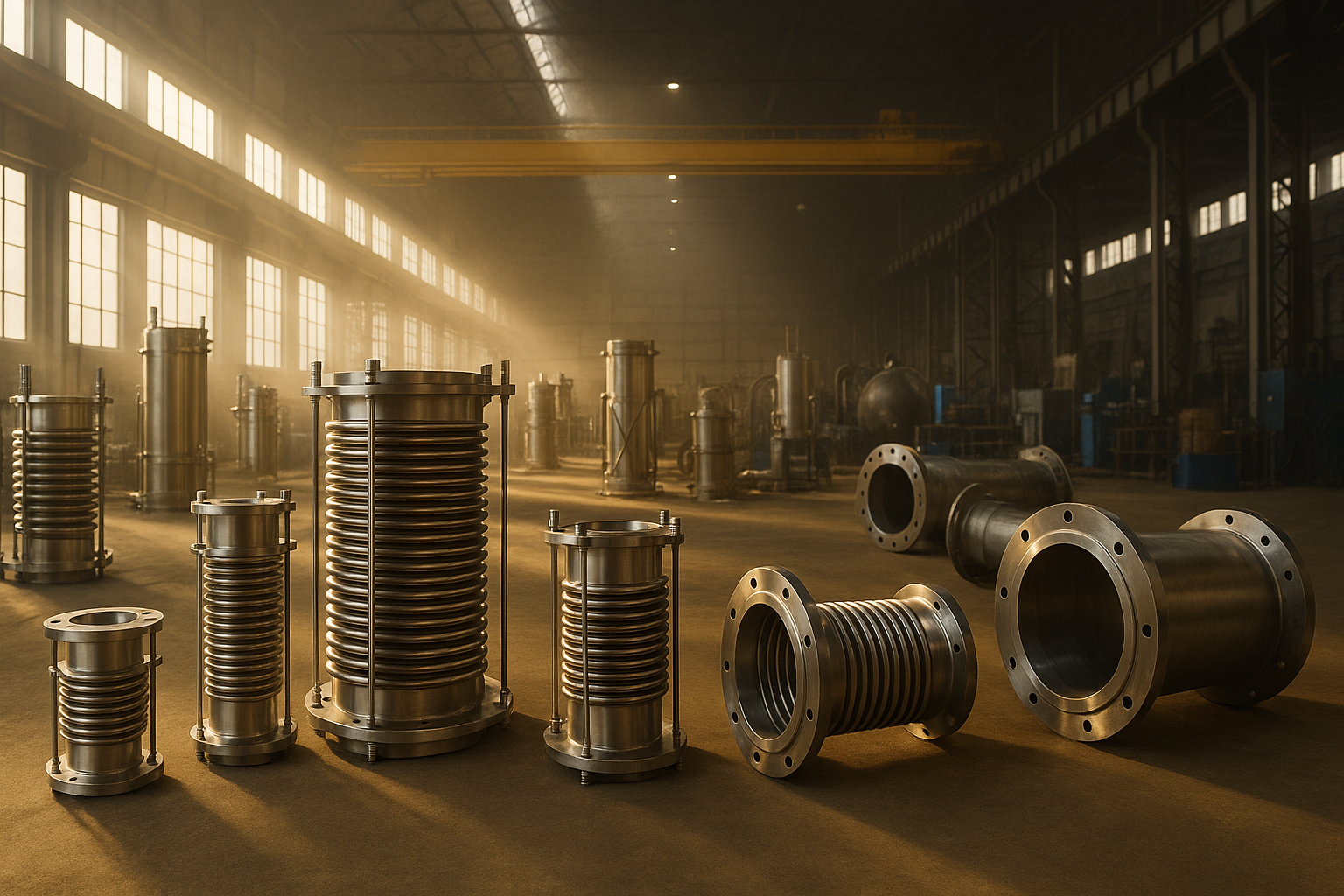

Exhaust & Engine Bellows

Exhaust/engine bellows are thin-gauge metallic bellows assemblies engineered for engine and turbine exhaust lines to absorb axial thermal growth, isolate vibration, and reduce nozzle loads. Designed and manufactured by Athulya Bellows per EJMA/ASME practices for reliable service in high-temperature gas streams.

Key Features

• Optimized for axial movement and vibration attenuation on engine/generator sets.

• Single or multi-ply bellows construction for flexibility and fatigue life.

• Internal flow sleeve/liner options to stabilize gas flow and protect convolutions.

• End connections: flanged or weld ends; drilling to ANSI/EN/IS or client spec.

• External protective covers/insulation available for personnel and heat shielding.

• Control units (tie/limit rods) if restraint is specified by system design.

Applications

• Diesel/gas engine gensets, turbocharger outlets, engine test cells.

• Gas turbine exhaust, auxiliary boiler exhaust, HRSG/stack connections.

• Process/marine engine exhaust lines requiring reduced nozzle loads and vibration control.

Technical Data

| Parameter | Value / Range | Notes |

|---|---|---|

| Nominal Size | Project-specific | Engineered to engine/exhaust duct dimensions |

| Pressure Class | As per design/service | Typical exhaust service; restraint if required |

| Temperature | Material/service dependent | Grade & liner selection per gas temp/medium |

| Movement Capability | Axial (primary); limited lateral if specified | Preset/cold-spring available |

| Materials | SS 304 / 316 / 321 / 310; special alloys | Selection based on temperature & corrosion |

| End Connections | Flanged / Welded | Drilling to ANSI/EN/IS or client standard |

| Accessories | Internal sleeves/liners, external covers/insulation, tie/limit rods | Shipping rods removed at installation |

| Testing | Hydro / pneumatic / leak checks as specified | Material traceability; certificates on request |

Design Options

• Multi-ply bellows for higher flexibility & cycle life.

• Single-flow vs. double-sleeve liner concepts for flow stabilization.

• External covers, insulation jackets, and removable sections for maintenance.

• Factory preset / cold-spring to maximize in-service capability.

Quality & Testing

• Designed & manufactured per EJMA/ASME practices.

• Hydrostatic / pneumatic testing; optional dye-penetrant, helium leak, and cycle testing.

• Full documentation and certificates on request.

Prefer a quick review? Email your specs to sales@athulyabellows.com.