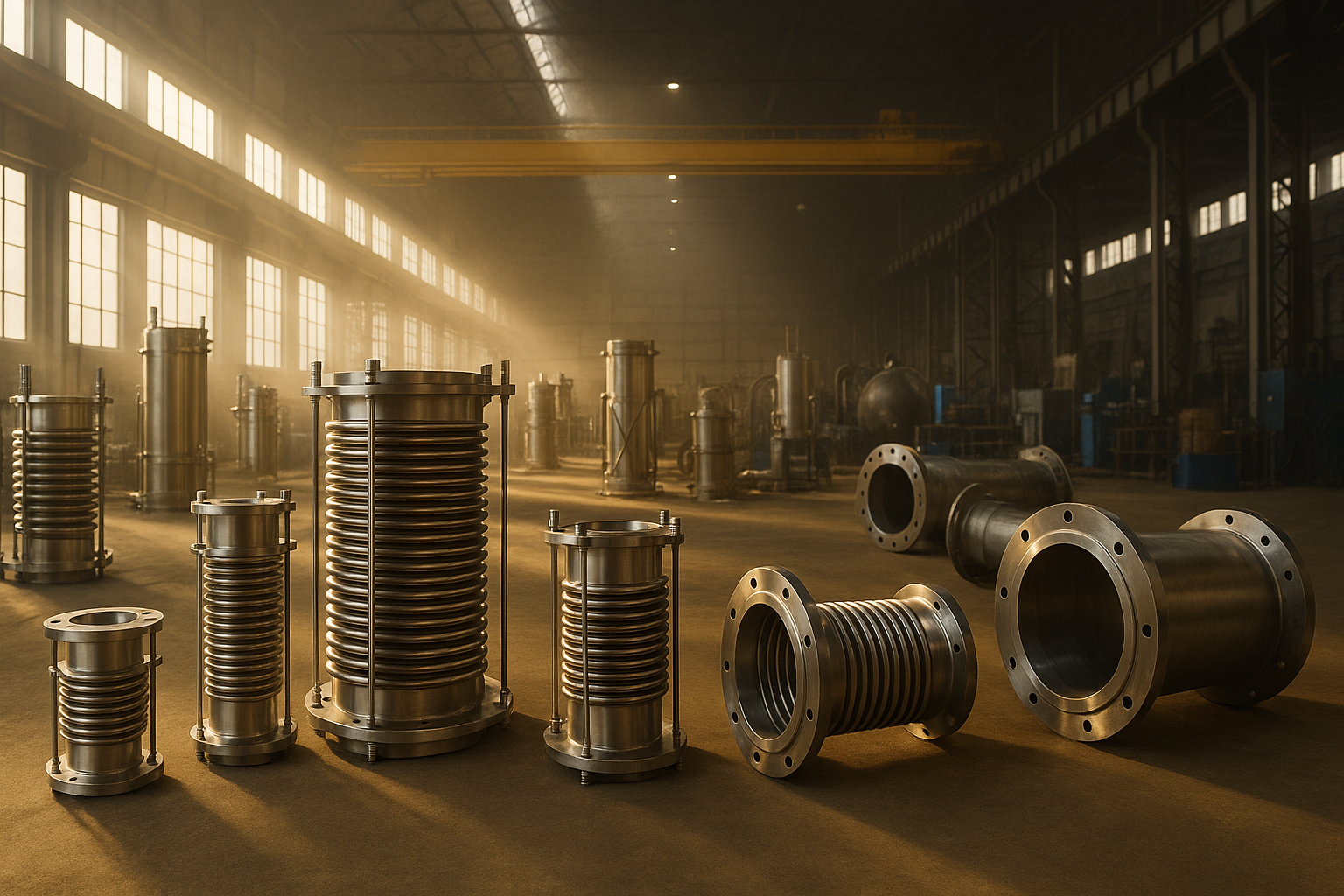

Universal (Tied) Expansion Joints

Universal (Tied) Expansion Joints comprise two bellows elements separated by a center spool and equipped with external tie rods. The tie rods restrain pressure thrust, allowing the joint to accommodate substantial lateral movement (with limited axial) while minimizing load on anchors and adjacent equipment. Engineered by Athulya Bellows in line with EJMA practices, these assemblies deliver reliable service in demanding pipe systems.

Key Features

• Double-bellow construction with center spool for higher lateral flexibility.

• Tie rods restrain pressure thrust → reduced anchor loads and smaller guides.

• Handles lateral offset plus small axial movement (presetting optional).

• Available in single or multi-ply bellows for improved cycle life.

• End connections: flanged or weld ends; custom drilling patterns available.

• Optional internal flow liner for high velocity or abrasive media.

Applications

• Long straight runs requiring lateral absorption with limited anchoring.

• Steam/condensate, hot air, and process lines in power & utility services.

• Refineries, petrochemical & chemical plants – pump/turbine connections.

• Steel & cement plants, HVAC & district heating/cooling networks.

• General industrial pipelines needing restrained joints to protect equipment.

Technical Data (Typical Ranges)

| Parameter | Range | Notes |

|---|---|---|

| Nominal Size | DN 50 – DN 6000 | Custom diameters on request |

| Pressure Rating | Vacuum to high pressure | Tie rods sized to restrain thrust |

| Temperature | −60°C to +1200°C | Depends on grade & service |

| Lateral Movement | Up to large offsets (project-specific) | Function of convolution count & length |

| Axial Movement | Limited (with preset if required) | Pressure thrust restrained by ties |

| Materials | SS 304 / 316 / 321 / 310; special alloys | Hardware in CS/SS; coatings available |

| End Connections | Flanged / Welded | To client standard (ANSI/EN/IS, etc.) |

| Accessories | Tie rods, limit rods, internal liners, covers | With preset & cold-spring options |

Design Options

• Multi-ply bellows for higher flexibility & fatigue life.

• Control units: tie/limit rods with spherical or clevis ends.

• Internal liners, external protective covers, insulation jackets.

• Surface protection for CS hardware (paint, zinc, or client-specified).

• Factory preset/cold-spring to optimize installed movement capability.

Quality & Testing

• Designed and manufactured as per EJMA/ASME practices.

• Hydrostatic / pneumatic pressure testing for each assembly.

• Optional NDT: dye penetrant, helium leak, and cycle testing.

• Full material traceability with certificates on request.

Prefer a quick review? Email your specs to sales@athulyabellows.com.