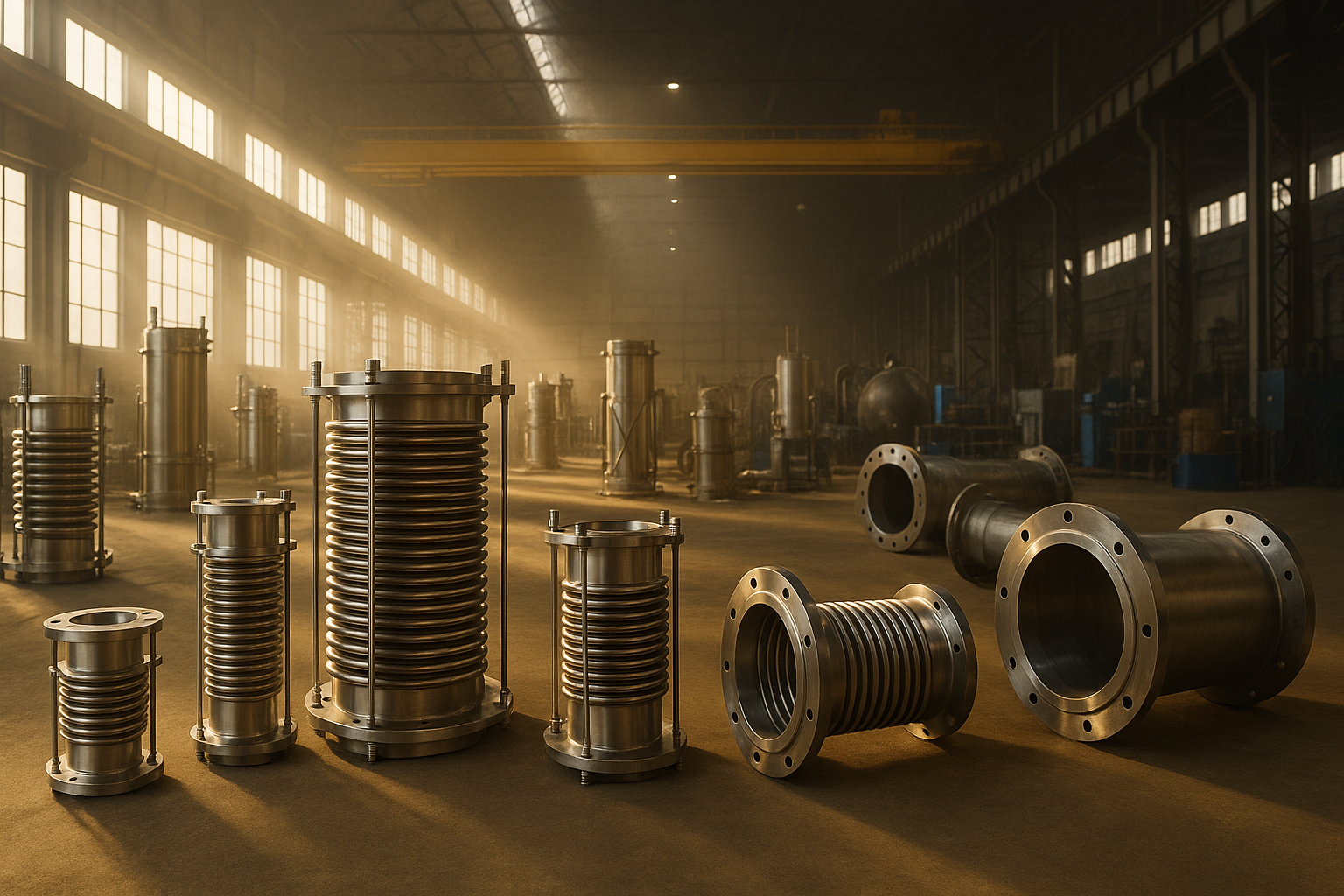

Flexible Metal Hose Assemblies

Athulya’s flexible metal hose assemblies combine annular corrugated stainless-steel hose with single or double SS wire braid to provide pressure-tight flexibility, vibration isolation, and thermal movement accommodation in compact spaces. Assemblies are custom-engineered with end connections to suit your service and site conditions, manufactured in line with EJMA/ASME practices.

Key Features

• Annular corrugations for high flexibility and pressure capability.

• Single / Double braid options to match pressure and pulsation requirements.

• Excellent for vibration absorption, pump/compressor connections, and misalignment.

• Wide media compatibility with stainless-steel wetted parts; leak-tight construction.

• End connections: flanged, weld ends, threaded (BSP/NPT), Camlock/quick-couplings as required.

• Optional external armor, spring guards, fire sleeves and bend restrictors for protection.

Applications

• Pump/compressor suction & discharge, turbine tie-ins, skid packages.

• Steam, condensate, hot oil, air/gas lines; cryogenic to high-temperature services.

• Refineries, petrochemicals, chemicals, power, steel & cement utilities and process lines.

• Where space is limited and vibration/thermal movement must be managed safely.

Technical Data

| Parameter | Value / Range | Notes |

|---|---|---|

| Nominal Size | Project-specific | Hose ID/OD and braid selection per service |

| Pressure Class | As per design/service | Single vs double braid to suit pressure & pulsation |

| Temperature | Material/service dependent | Stainless grade selected per medium & temperature |

| Construction | Annular corrugated hose + SS braid | Optional external armor / spring guard |

| Movement Capability | Multi-plane flexing / vibration isolation | Minimum bend radius set per size & routing |

| Materials | Hose: SS 304 / 316 / 321; Braid: SS 304 / 316 | Special alloys on request |

| End Connections | Flanged / Welded / BSP / NPT / Quick-couplings | Drilling to ANSI/EN/IS or client standard |

| Accessories | Armor, spring guards, fire sleeve, liners | Tested assemblies supplied with caps/plugs |

| Testing | Hydro / pneumatic as specified | Leak & dimensional checks; certificates on request |

Design Options

• Single/Double braid; custom braid angles for pulsation control.

• External interlocked guard or wire braid shield for abrasion protection.

• Fire sleeve / insulation jackets; tagged flow direction and bend radius markers.

• Factory preset lengths, orientation match-marking, and QA documentation.

Quality & Testing

• Hydrostatic / pneumatic pressure testing per specification.

• Optional helium leak, dye-penetrant on welds, and cycle testing.

• Full material traceability; test reports when requested.

Prefer a quick review? Email your specs to sales@athulyabellows.com.