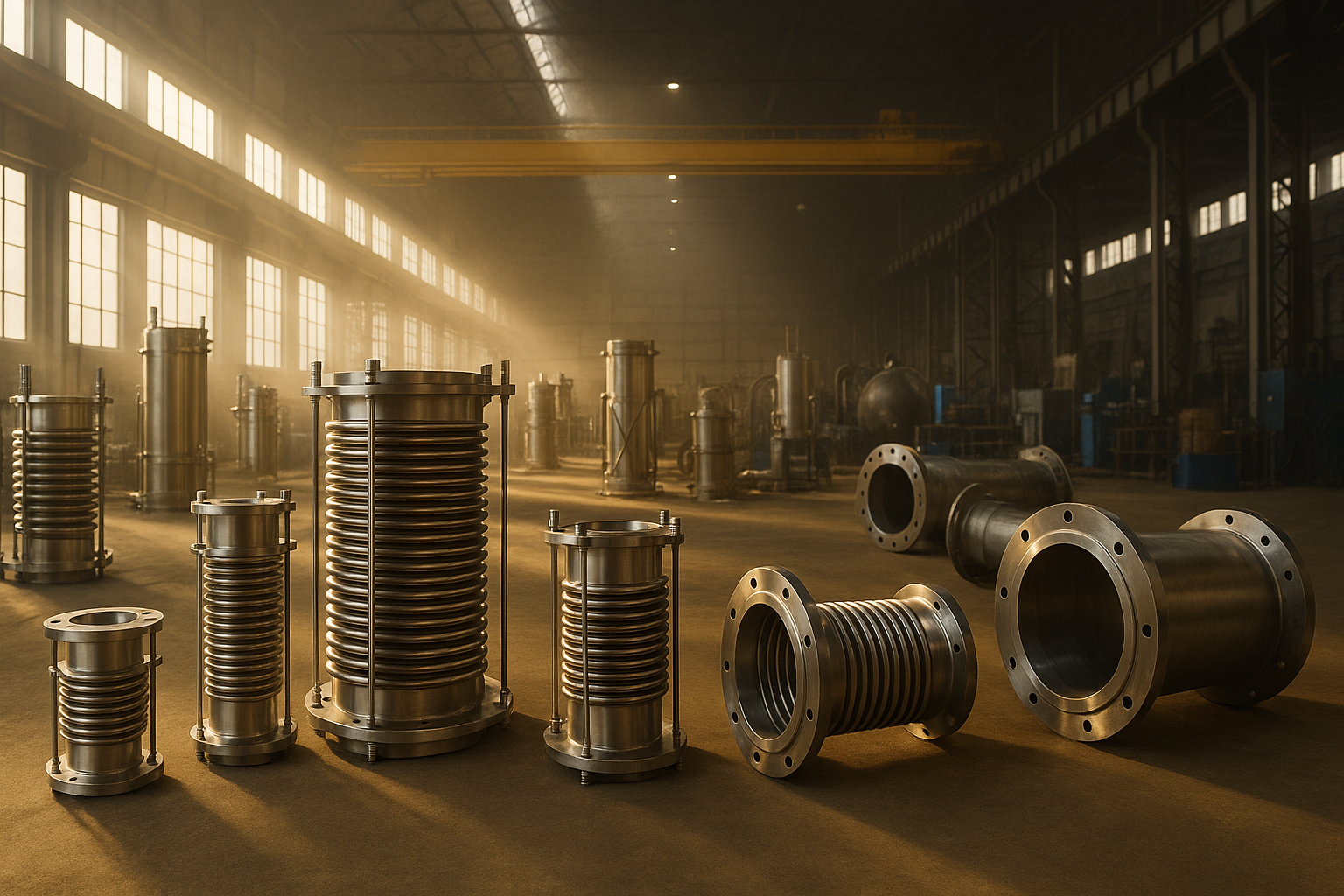

Pressure Balanced (Inline) Expansion Joints

Inline pressure-balanced assemblies use a balancing bellows connected through tie hardware so the pressure thrust is self-cancelled within the unit. This allows significant axial movement with minimal loads on anchors and equipment—ideal where structural limits prevent large fixed anchors. Designed and manufactured by Athulya Bellows per EJMA/ASME practices.

Key Features

• Internal pressure thrust balancing → low anchor load requirement.

• Handles inline axial expansion/contraction; lateral/rotation restrained by design.

• Configuration: flow bellows + balancing bellows linked by tie/torque hardware.

• Single or multi-ply bellows construction for fatigue life.

• End connections: flanged or weld ends; drilling to client standard (ANSI/EN/IS).

• Optional internal flow liner for velocity/particulate service.

Applications

• Steam/condensate, hot air, and process lines where anchors cannot take thrust.

• Pump/turbine connections and equipment nozzles requiring low external loads.

• Refineries, petrochemicals, chemicals, power, steel & cement process piping.

• District heating/cooling mains; long straight runs with restricted anchoring.

Technical Data

| Parameter | Value / Range | Notes |

|---|---|---|

| Nominal Size | Project-specific | Engineered per application |

| Pressure Rating | As per design/service | Balancing section sized to cancel thrust |

| Temperature | Material/service dependent | Grade selection per medium & temp |

| Axial Movement | Project-specific | Presetting/cold-spring on request |

| Lateral / Angular | Restrained | Use lateral or elbow PBEJ for direction change |

| Materials | SS 304 / 316 / 321 / 310; special alloys | Hardware in CS/SS; coatings available |

| End Connections | Flanged / Welded | Drilling to client standard |

| Accessories | Balancing bellows, tie/limit rods, liners, protective covers | Shipping rods removed at install |

Design Options

• Multi-ply bellows for higher flexibility & fatigue life.

• Tie/limit hardware with clevis or spherical ends; removable pins.

• Internal liners, external protective covers, insulation jackets.

• Surface protection for CS parts (paint, zinc, or client-specified).

• Factory preset / cold-spring to maximize in-service capability.

Quality & Testing

• Designed and manufactured as per EJMA/ASME practices.

• Hydrostatic / pneumatic pressure testing of each assembly.

• Optional NDT: dye-penetrant, helium leak, and cycle testing.

• Full material traceability with certificates on request.

Prefer a quick review? Email your specs to sales@athulyabellows.com.