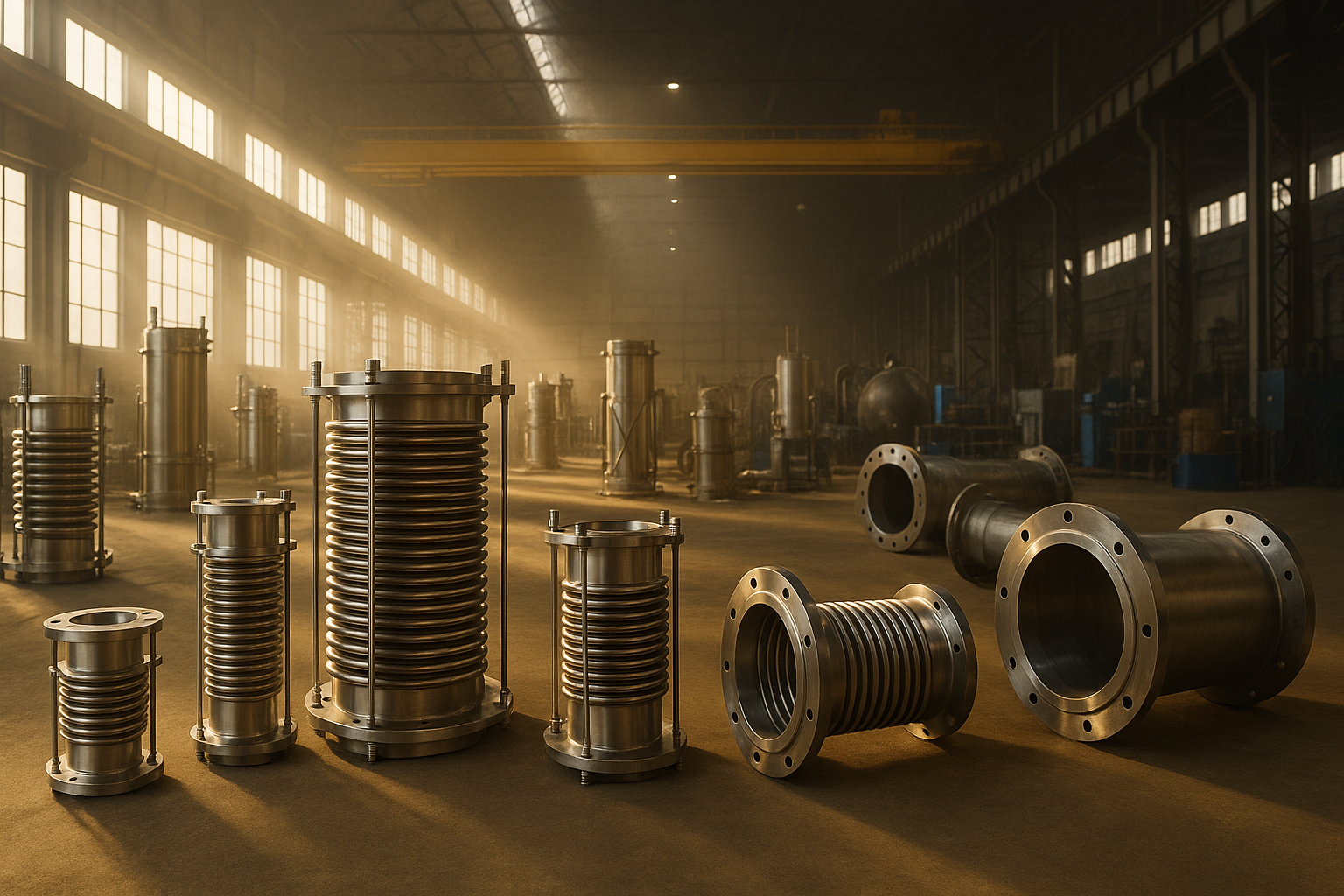

Gimbal Expansion Joints

Gimbal Expansion Joints use a pair of hinge assemblies mounted to a common gimbal ring, allowing angular rotation in any plane while restraining pressure thrust. Deployed in pairs (or with a hinged unit), they absorb thermal growth across three-dimensional piping layouts with minimal anchor loads. Designed and manufactured by Athulya Bellows as per EJMA/ASME practices for reliable service in demanding applications.

Key Features

• Gimbal hardware (lugs, pins, arms, ring) restrains pressure thrust and shear forces.

• Permits angular movement in multiple planes; axial and lateral are restrained by design.

• Ideal for expansion loops and 3D piping where rotation must be controlled.

• Single or multi-ply bellows for improved flexibility and fatigue life.

• End connections: flanged or weld ends; drilling to ANSI/EN/IS or client spec.

• Optional internal flow liner for high-velocity/particulate service.

Applications

• Steam/hot air lines and process headers with fixed anchors and direction changes.

• Refineries, petrochemical & chemical plants—equipment tie-ins and manifolds.

• Power, steel & cement plants; district heating/cooling and HVAC mains.

• Large ducting/pipe systems needing angular rotation without axial thrust on anchors.

Technical Data (Typical Ranges)

| Parameter | Range | Notes |

|---|---|---|

| Nominal Size | DN 150 – DN 6000 | Custom diameters on request |

| Pressure Rating | Vacuum to high pressure | Gimbal hardware sized to restrain thrust |

| Temperature | −60°C to +1200°C | Material/service dependent |

| Movement Type | Angular (multi-plane via gimbal) | Axial & lateral restrained by design |

| Angular Movement | Project-specific (degrees per joint) | Function of bellows geometry & length |

| Materials | SS 304 / 316 / 321 / 310; special alloys | Hardware in CS/SS; coatings available |

| End Connections | Flanged / Welded | To client standard (ANSI/EN/IS, etc.) |

| Accessories | Gimbal assemblies, limit rods, internal liners, covers | Preset / cold-spring options available |

Design Options

• Multi-ply bellows for higher flexibility & fatigue life.

• Gimbal arms with clevis or spherical ends; removable hinge pins.

• Internal flow liners, external protective covers, insulation jackets.

• Surface protection for CS parts (paint, zinc, or client-specified).

• Factory preset / cold-spring to optimize installed angles.

Quality & Testing

• Designed and manufactured as per EJMA/ASME practices.

• Hydrostatic / pneumatic pressure testing of each assembly.

• Optional NDT: dye-penetrant, helium leak, and cycle testing.

• Full material traceability with certificates on request.

Prefer a quick review? Email your specs to sales@athulyabellows.com.