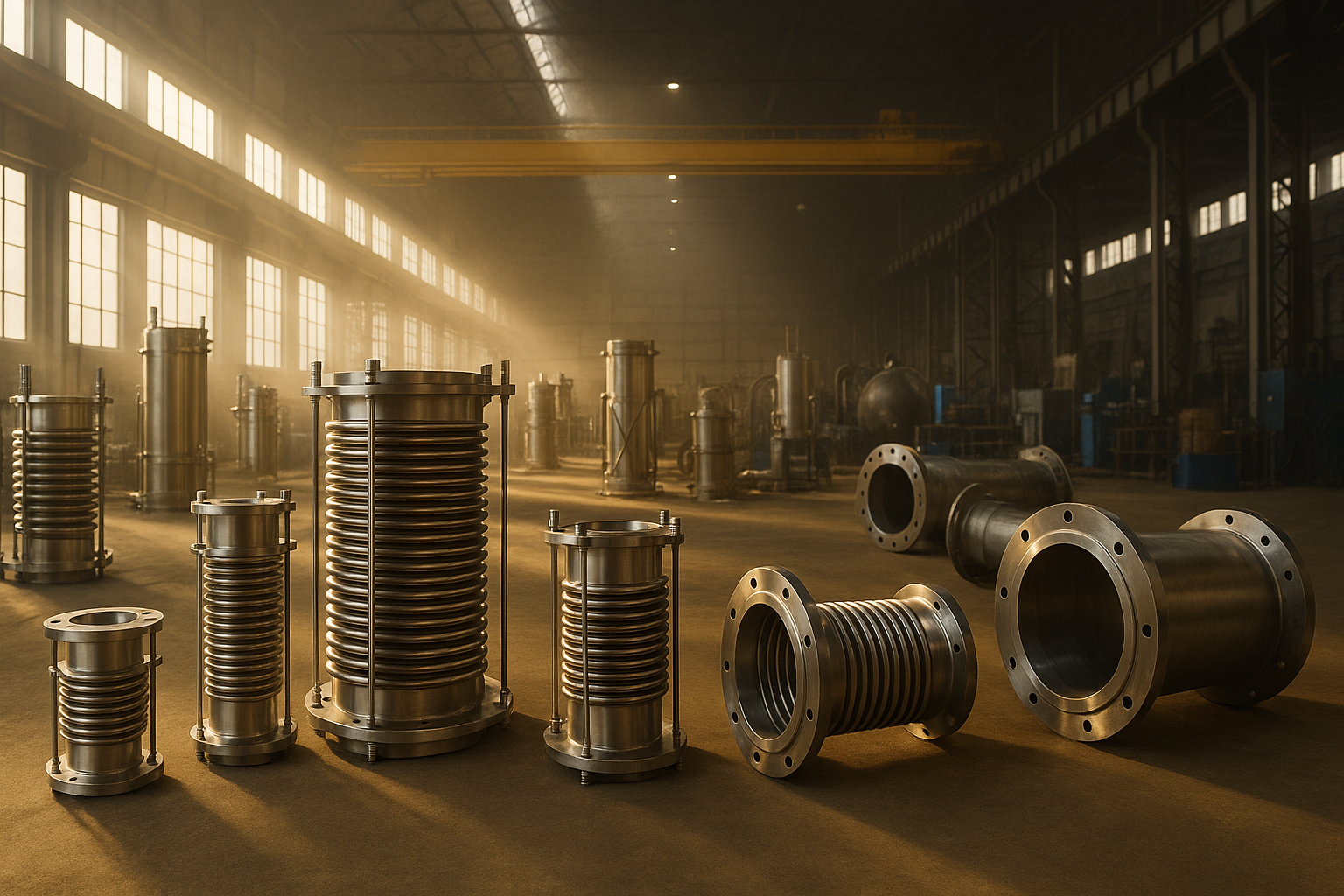

Externally Pressurized Expansion Joints

Externally pressurized joints are designed for large axial movement applications. The bellows is stabilized by routing the pressure to the outside of the convolutions, which improves resistance to squirm and enables long stroke capability with dependable guidance. Engineered and manufactured by Athulya Bellows in line with EJMA/ASME practices.

Key Features

• Purpose-built for long axial travel with stable bellows geometry.

• External pressure path helps resist squirm/buckling at extended strokes.

• Guide sleeves/housings maintain alignment through the movement range.

• Available in single or multi-ply bellows for flexibility and fatigue life.

• End connections: flanged or weld ends; drilling to ANSI/EN/IS or client standard.

• Optional internal flow liners and external protective covers.

Applications

• Steam/condensate and hot air lines requiring large axial absorption in limited space.

• Long straight runs between anchors; equipment nozzles where low reaction loads are desired.

• Power, refinery, petrochemical, chemical, steel & cement utility/process piping.

Technical Data

| Parameter | Value / Range | Notes |

|---|---|---|

| Nominal Size | Project-specific | Engineered to pipeline size and stroke |

| Pressure Rating | As per design/service | External pressurization & sleeve guide sized for duty |

| Temperature | Material/service dependent | Grade selection per medium & temperature |

| Movement Capability | Axial (long stroke) | Preset / cold-spring available as specified |

| Materials | SS 304 / 316 / 321 / 310; special alloys | Hardware in CS/SS; coatings available |

| End Connections | Flanged / Welded | Drilling to ANSI/EN/IS or client standard |

| Accessories | Guide sleeves/housings, internal liners, protective covers | Shipping rods removed at installation |

| Testing | Hydro / pneumatic / leak checks as specified | Material traceability; certificates on request |

Design Options

• Single or multi-ply bellows; stroke set per line growth.

• Internal flow sleeves/liners; external covers and insulation jackets.

• Control/limit hardware where system restraint is specified.

Quality & Testing

• Designed & manufactured per EJMA/ASME practices.

• Hydrostatic/pneumatic testing; optional DPT, helium leak, and cycle tests.

• Documentation and material certificates on request.

Prefer a quick review? Email your specs to sales@athulyabellows.com.