Engineered Reliability

Metallic bellows and expansion joints designed to absorb vibration, thermal movement, and pressure cycles—keeping your lines safe and stable.

Transparent Pricing

Clear quotations, material traceability, and delivery timelines—so you know exactly what you’re getting and when.

Qualified Manufacturing

Built by trained technicians using proven forming and welding processes, inspected for leak-tightness and dimensional accuracy.

Custom Solutions

Tailor-made bellows for your media, temperature, and movement—materials, ends, and ply count optimized for service life.

Your Trusted Partner in Expansion Joints & Bellows

Athulya Bellows is a leading manufacturer of metallic expansion joints, bellows, and flexible connectors engineered to absorb vibration, pressure, and thermal movements in critical piping systems.

Backed by decades of design expertise, modern machinery, and a skilled workforce, Athulya Bellows delivers solutions that enhance reliability and extend service life for industries worldwide. Our products are custom-built to international standards and undergo rigorous quality checks at every stage.

Serving power, steel, cement, refineries, petrochemicals, fertilizers, and infrastructure projects, we have become a trusted partner for industries that demand precision, safety, and performance.

Quality

Each bellow and expansion joint is manufactured with certified materials and tested for leak-tightness, strength, and dimensional accuracy.

Reliability

Trusted in mission-critical applications where consistent performance and safety are non-negotiable.

Innovation

Custom-engineered designs tailored to client requirements, supported by ongoing R&D and process improvement.

Complete Product Range for Piping & Ducting Movement Control

Athulya Bellows designs and manufactures metallic expansion joints, fabric/rubber joints, and flexible hose assemblies engineered to absorb axial, lateral, and angular movements, reduce vibration, and protect equipment across demanding industries.

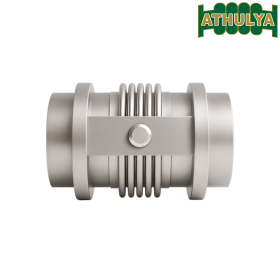

Schedule An AppointmentAxial Expansion Joints

Single/multi‑ply metallic bellows that absorb axial thermal growth and pressure thrust in straight runs.

Read More

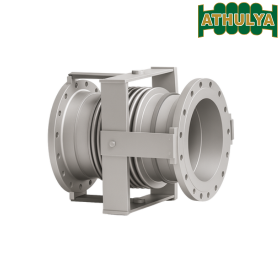

Universal (Tied) Joints

Two bellows with a center spool and tie rods to accommodate lateral movement with minimal anchor load.

Read More

Hinged Expansion Joints

Hinge hardware permits angular rotation in one plane while restraining pressure thrust and piping forces.

Read More

Gimbal Expansion Joints

Dual‑hinge ring assembly enables angular rotation in any plane—ideal for 3D piping loops.

Read More

Pressure Balanced (Inline)

Balances pressure thrust while absorbing axial movement—protects anchors and equipment.

Read More

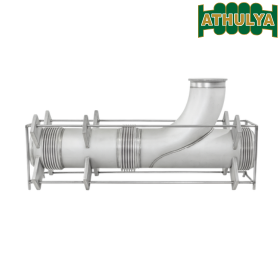

Pressure Balanced (Elbow)

For 90° turns—absorbs axial movement without imposing thrust on elbow branches.

Read More

Externally Pressurized

Handles large axial movement at higher pressures; stable bellows under external pressurization.

Read More

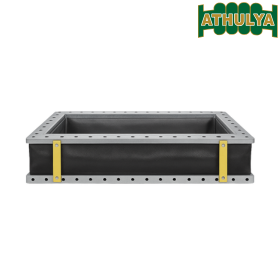

Rectangular Bellows

Corner‑formed or mitred construction for ducts, air/gas lines, and large cross‑sections.

Read More

Rubber Expansion Joints

Elastomeric joints for vibration isolation and noise reduction; multiple arch/flanged styles.

Read More

Fabric/Duct Expansion Joints

For high‑temperature gas ducts; multi‑layer fabrics manage thermal movement and misalignment.

Read More

Flexible Metal Hose Assemblies

Corrugated stainless steel hoses with braid for vibration absorption and flexible hookups.

Read More

Exhaust & Engine Bellows

Engine/exhaust line bellows designed to handle pulsation, vibration, and thermal cycling.

Read More

PTFE‑Lined Joints

Corrosion‑resistant joints for aggressive media; PTFE liners protect wetted surfaces.

Read More

Accessories & Options

Internal liners, external covers, tie/limit rods, purges, and insulation sets tailored to service.

Read More

We will get back to you within 24 hours, or call us directly at +91 7043136166 or email us at sales@athulyabellows.com

Frequently Asked Questions

We design and manufacture metallic expansion joints (axial, lateral, universal/tied, hinged, gimbal, pressure balanced inline & elbow, externally pressurized), rectangular bellows, rubber & fabric/duct expansion joints, exhaust/engine bellows, PTFE‑lined joints, and flexible metal hose assemblies with end fittings.

Yes. We engineer custom sizes, ply combinations, convolution profiles, tie‑rod/hinge/gimbal hardware, liners, covers and end connections to match your pressure, temperature, movement and space constraints. Share line size, design pressure/temperature, movement (axial/lateral/angular), and end type for a fast quote.

Common bellows materials include SS304/304L, SS316/316L; on request we can build in higher‑alloy steels or nickel‑based grades for demanding media/temperatures. End fittings, flanges and hardware are matched to service and standards. Rubber/fabric joints use reinforced elastomers and high‑temp fabrics as per duty.

Match the joint to the predominant movement and system layout: axial (axial bellows, externally pressurized), lateral (lateral/universal tied), angular (hinged/gimbal), or combined (pressure balanced for minimal anchor loads; rectangular for ducts). We’ll validate movements, spring rates and anchor loads from your piping data.

Each assembly undergoes dimensional checks and pressure tests (typically hydro or pneumatic as applicable). Welds are qualified to procedure, and accessories (liners, covers, tie rods, hinges, gimbals) are verified for travel and stops. Test certificates and inspection records can be supplied with dispatch.

Yes. For custom items we share GA/approval drawings indicating overall length, convolution geometry, end type, hardware, movements, spring rates and test details before fabrication.

Standard sizes are often dispatched quickly; custom designs depend on size, material and hardware. Share your required date—our team will confirm the build schedule. We accept single‑piece orders for most custom bellows.

Yes—installation guides are provided. Key points: keep the bellows neutral at fit‑up, align piping, support loads properly, remove shipping bars only after installation, and do not use bellows to correct misalignment. We can advise on anchors, guides and cold‑spring if needed.

Absolutely. Send dimensions (overall length, live length, OD/ID), end type, movement and service data—or share the old part for reverse engineering—and we will supply a drop‑in replacement or an upgraded design.

Line size & end connection, design pressure/temperature, medium, required movements (axial/lateral/angular), available face‑to‑face length, hardware (tied/hinged/gimbal/liners/covers), quantity and delivery location. Drawings/photos help accelerate engineering.

Service life depends on movement cycles, temperature, pressure and alignment. Ensure proper guiding/anchoring, avoid torsion, protect from external damage, and inspect periodically for leaks or deformation. Adding liners/covers can improve life in abrasive or high‑velocity flow.

Yes, we ship across India and internationally through dependable logistics partners. Packaging is engineered to protect convolutions and hardware in transit.

Couldn’t find your answer? Contact Us Now