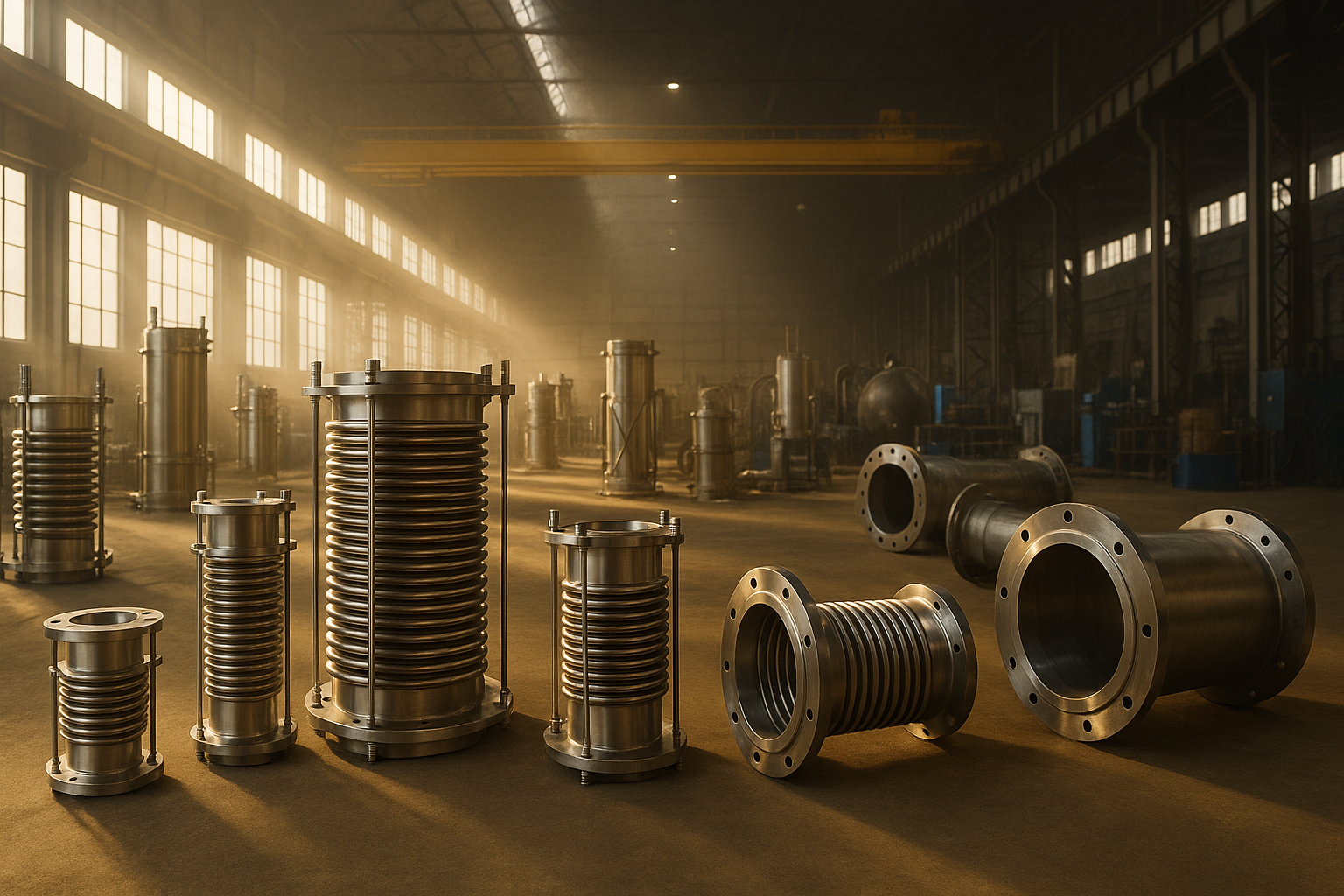

PTFE-Lined Expansion Joints

PTFE-lined expansion joints combine a metallic bellows body with a continuous PTFE liner to protect against corrosive media while absorbing pipeline movements. The liner isolates the bellows from process fluids, enhancing corrosion resistance and service life. Designed and manufactured by Athulya Bellows following EJMA/ASME practices for reliable performance in aggressive services.

Key Features

• Full-length PTFE liner shields metallic bellows from corrosive media.

• Handles axial movement; configurations available for lateral/Angular with control units.

• Multi-ply bellows options for higher flexibility and fatigue life.

• End connections: flanged or weld ends; drilling to ANSI/EN/IS or client standard.

• Optional external covers and insulation; shipping rods for transport safety.

• Engineered to suit process chemistry, temperature, and velocity conditions.

Applications

• Chemical, petrochemical & pharma lines carrying acids, alkalis, and solvents.

• Refinery utility/process lines requiring corrosion protection at expansion points.

• Where metal-media compatibility is critical but movement must be accommodated.

Technical Data

| Parameter | Value / Range | Notes |

|---|---|---|

| Nominal Size | Project-specific | Engineered per pipeline size |

| Pressure Rating | As per design/service | Function of bellows ply, braid/control units, and liner |

| Temperature | Service-dependent | PTFE liner & metal grade selected per medium/temperature |

| Movement Capability | Axial (primary); Lateral/Angular via design | Preset / cold-spring available |

| Liner Material | PTFE (fluoropolymer) | Continuous sleeve/liner through the bellows |

| Bellows & Hardware | SS 304 / 316 / 321 / 310; special alloys on request | Frames/hardware in CS/SS; coatings if specified |

| End Connections | Flanged / Welded | Drilling to ANSI/EN/IS or client standard |

| Accessories | Control (tie/limit) rods, external covers | Shipping rods removed at installation |

| Testing | Hydro / pneumatic / leak checks as specified | Material traceability; certificates on request |

Design Options

• Single or multi-ply bellows; liner extensions and flare options at flanges.

• Control units with clevis/spherical ends; removable pins.

• External protective covers and insulation jackets for safety and heat shielding.

Quality & Testing

• Designed and manufactured per EJMA/ASME practices.

• Hydrostatic/pneumatic testing; optional dye-penetrant, helium leak, and cycle tests.

• Full documentation and material certificates available on request.

Prefer a quick review? Email your specs to sales@athulyabellows.com.