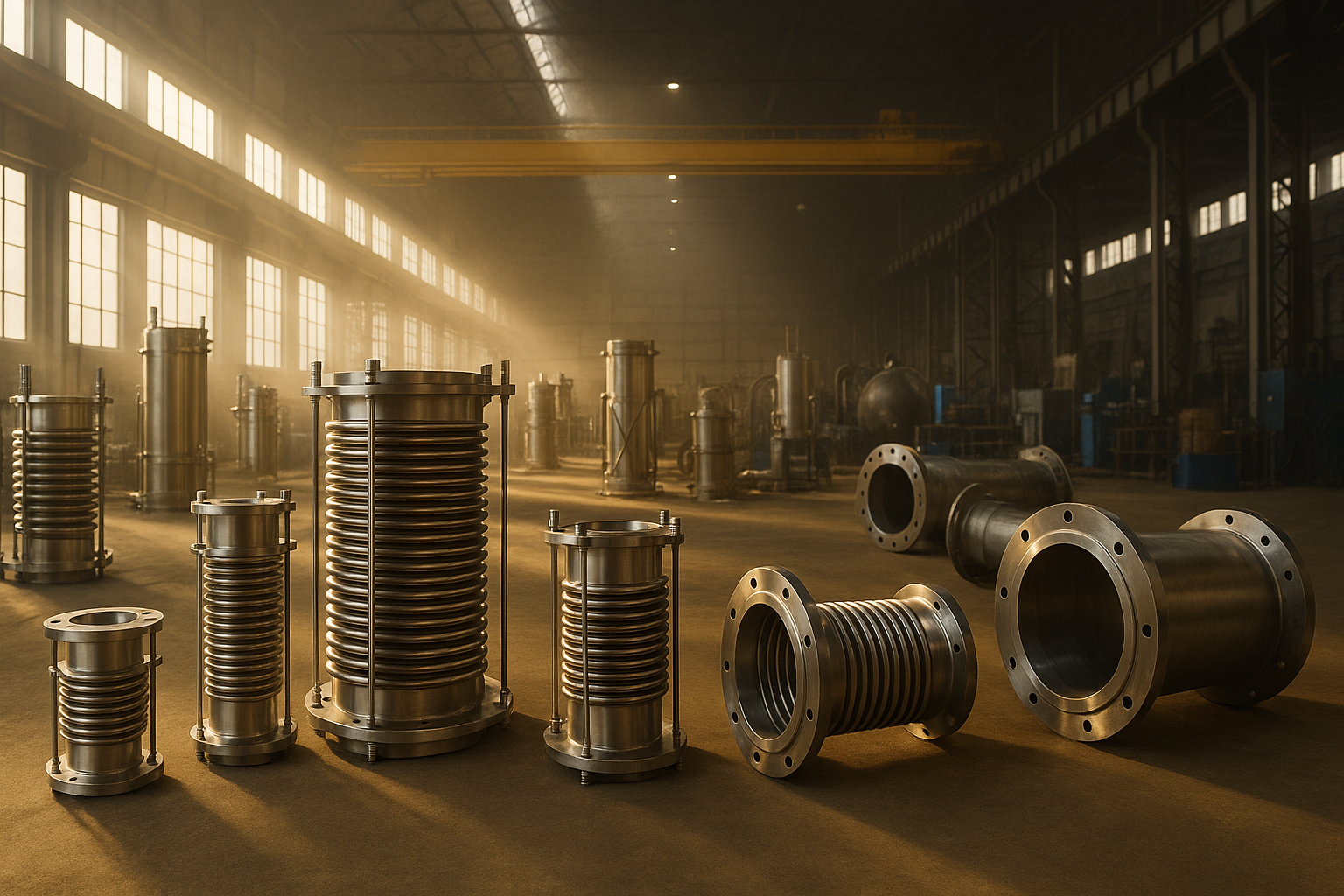

Hinged Expansion Joints

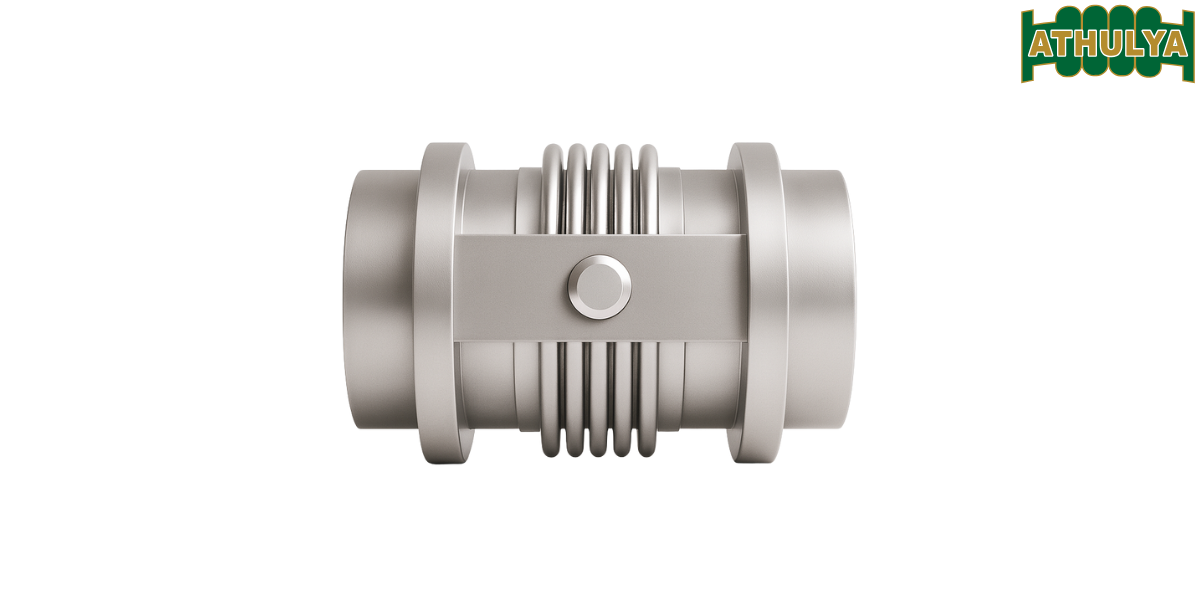

Hinged Expansion Joints consist of a bellows element fitted with hinge hardware (hinge pins, lugs, and arms) that restrains pressure thrust and allows pure angular movement in a single plane. Used in pairs or sets of three, they absorb thermal expansion while keeping anchor loads low—ideal where axial movement must be restrained but rotation is required. Designed and manufactured by Athulya Bellows following EJMA/ASME practices.

Key Features

• Hinge mechanism restrains pressure thrust; anchors see minimal load.

• Allows angular rotation in one plane; axial and lateral movements are restrained by design.

• Used in pairs or three-joint systems to absorb pipeline expansion between fixed points.

• Available as single or multi-ply bellows for improved flexibility and cycle life.

• End connections: flanged or weld ends; drilling to client standard (ANSI/EN/IS).

• Optional internal flow liner for high velocity/particulate service.

Applications

• Steam, hot air, and process lines where axial restraint and controlled angular rotation are required.

• Refineries, petrochemicals, and chemical plants—equipment connections and long runs with fixed anchors.

• Power, steel & cement plants, district heating/cooling, and HVAC headers/manifolds.

• Any line needing rotation at set points to manage expansion without large anchor structures.

Technical Data (Typical Ranges)

| Parameter | Range | Notes |

|---|---|---|

| Nominal Size | DN 150 – DN 6000 | Custom diameters available |

| Pressure Rating | Vacuum to high pressure | Hinge hardware sized to restrain thrust |

| Temperature | −60°C to +1200°C | Material/service dependent |

| Movement Type | Angular (single plane) | Axial & lateral restrained by hinges |

| Angular Movement | Project-specific (e.g., a few degrees per joint) | Function of bellows geometry & length |

| Materials | SS 304 / 316 / 321 / 310; special alloys | Hardware in CS/SS; coatings available |

| End Connections | Flanged / Welded | Drilling to standard or per spec |

Design Options

• Single or multi-ply bellows for higher flexibility & fatigue life.

• Hinge/limit hardware: clevis or spherical ends; removable hinge pins.

• Internal flow liners, external protective covers, insulation jackets.

• Surface protection for CS parts (paint, zinc, or client-specified).

• Factory preset / cold-spring to optimize installed angles.

Quality & Testing

• Designed and manufactured as per EJMA/ASME practices.

• Hydrostatic / pneumatic pressure testing of each assembly.

• Optional NDT: dye-penetrant, helium leak, and cycle testing.

• Full material traceability with certificates on request.

Prefer a quick review? Email your specs to sales@athulyabellows.com.